Laser Welding of Pillow plates

Low cost automatic Production of pillow plates

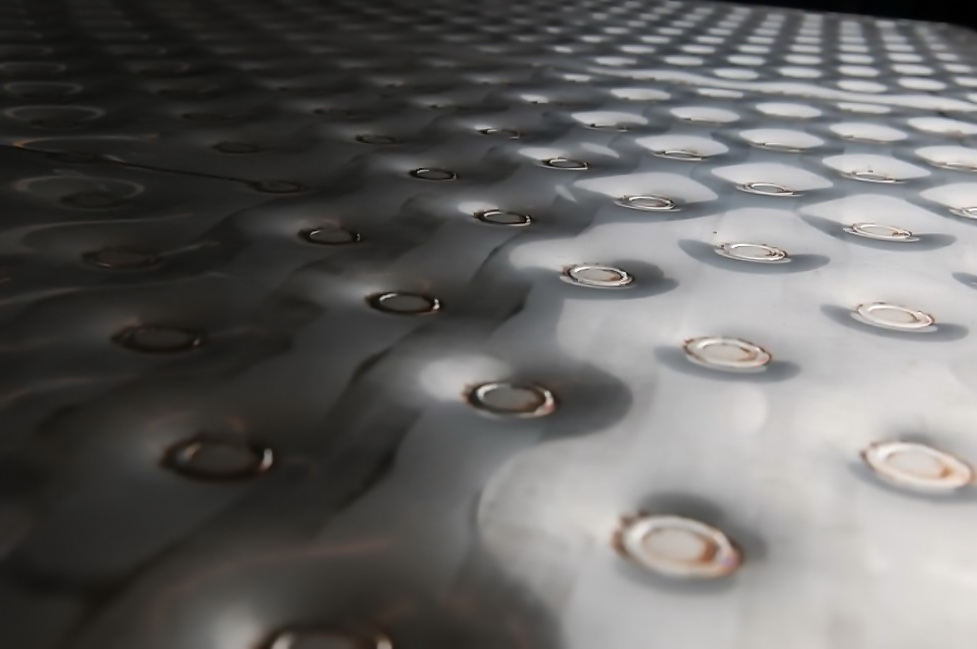

Pillow Plates, also called dimpled plates or thermo plates, consists of two stainless steel sheets that are laser welded together by welding a custom circle weld pattern. Then the plate is inflated by using water pressure, which creates a specific single or double embossed profile – the pillow plate, through which the cooling or heating is conducted. The thickness and the spot pattern are determined by the pressure requirements.

AFFORDABLE AND FAST PRODUCTION OF PILLOW PLATES AND DIMPLE PLATES

WOBBLE CUBE PLATEWELD MAKE IT POSSIBLE AND ECONOMICAL

The WOBBLE PlateWeld is a powerful welding system to produce pillow plates and dimple plates for the construction of isolated tanks and heat exchangers. The wobbling fiber laser allows to weld fast, producing up to 5 square meters pillow plate per hour. Also the weld depth and spot width are consistent and very well controlled, leaving the traditional TIG welding far behind in productivity. Especially in complex welding patterns, like cones or bottoms, the WobbleCube PlateWeld is an outstanding welding system. The high level of process automation make the Wobble PlateWeld easy to operate and requires a minimum of staffing.

Other benefits of Lasermach Wobble PlateWeld Laser Cube are:

- Able to weld combi of 0.3mm on 8mm

- Years of laser welding experience, resulting in maintenance and operator friendly design

- Unique wobble welding giving perfect result!

Sample Welding : Laser Welding of pillow plate : 0.8 mm stainless on 6 mm stainless steel welding with wobble laser

Products for cooling and heating of thermal processes

Dimple plate heat exchanger itself, can be an integral part as the product of heating or cooling of a thermal process. The process, the design and the application need specifies a single embossed or double embossed dimple plate heat exchanger. In addition, more complex heat exchanger systems may be constructed of a plurality of individual dimple plate heat exchanger plates of an open type stainless steel construction. Accordingly, the shape and size of the space conditions and the required heat exchanger surface justify the requirements.

Furthermore, the heating of the processes by means of integrating a dimple plate heat exchange or dimple plate system is performed primarily with the media such as water vapor, chemical vapors or thermal oils. In addition, the cooling of the processes is carried out by means of a dimple plate heat exchange or dimple plate system by ice water, water glycol mixtures and conventional or alternative refrigerants with pump, gravity or dx operation.

Consequently, an optimized guided channel inside the dimple plate is important in order to achieve the lowest pressure drop losses. Of course, a high quality laser welding technique is required.

Dimple Plate welding contours in any shape

By manufacturing on our Wobble Cube Plateweld CNC-controlled laser welding equipment, welding contours can be produced in any shape. On the one hand, this allows flexible shaping of the dimple plate. Thus, pillow plates in simple rectangular shape, can be produced just as easily as round plated or plates with complicated geometric outer contours. Cut-outs of any shape and size, e.g. for the feed-through of pipes or cables can be easily realized in this way. On the other hand, the flow arrangement for the medium in the pillow plate can also be flexibly designed by means of appropriate shape of weld seams. The flow arrangement can be easily adapted to the flow rate of the heating or cooling medium in the plate, thus optimizing heat transfer and pressure drop.

Dimple Plate welding contours optimizing heat transfer and pressure drop

For many applications in industrial process technology, dimple plates are technically and ecomically advantageous over conventional heat exchangers. The flexible design of each pillow plate allows tempering of products during other process steps. Apart a pillow plate fulfills a better mechanical resistance according thermal cycling.

Fields of application of dimple plates.

Primarily applicable for the following applications:

- Heating or cooling with stainless steel heat transfer dimple plates according to customer specifications

- The construction of cylindrical dimple plate jacketed tanks from heating or cooling zones for liquid temperature control

- The heat exchange for contaminated liquids

- Equipment with a need for regular and easy cleaning

- Cooling to near freezing

- The production of crushed ice

- The storage of cold as ice