The Basics of Spot Welding

Resistance spot welding can be used when there is a need to weld together two pieces of material up to 3~5 mm thick that are stacked on top of each other. This process often is used in the transportation and sheet metal forming industries for applications such as fabricating vehicle body parts and frames, as well as for welding office furniture and toolboxes.

The spot welding process uses two electrodes, one positioned at the bottom of the base material and one at the top. Pressure is applied between the two electrodes, which pushes the two pieces of metal together. A current passes between the electrodes, produces a weld, and fuses the two surfaces together. (more info on www.lowcostwelder.com)

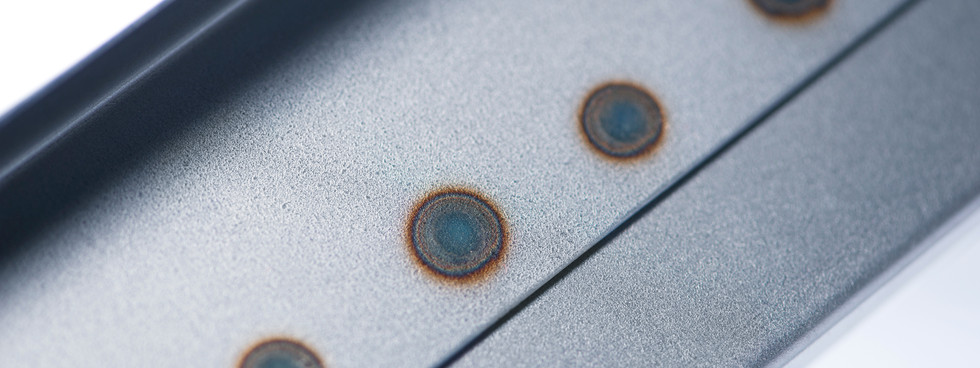

One challenge with spot welding is that when the two electrodes release, they leave an indentation on the base metal. In welding applications where aesthetic requirements are important, ridding the material of this indentation requires postweld grinding and often painting, which add time and cost to the process.

Spot welding typically is a manual process; it is difficult and expensive to automate, especially in low- to medium-volume applications. It also is challenging to establish a predictable process when using automated spot welding because the electrodes wear quickly, which means the process parameters and fit-up continually change. This also can affect the repeatability of part quality in spot welding. In addition, the robot necessary to complete automated spot welding is quite heavy and can be cumbersome, which is a drawback to implementation for many operations.

As a rule of thumb, very high part volume is necessary to efficiently automate spot welding. An example of this is automotive part manufacturing, which uses spot welding frequently. Spot welding excels in applications where part fit-up isn’t good and something is needed to press the two pieces together for welding. Spot welding also has a lower-cost point of entry; it requires purchasing a manual single-station spot welder only.

The Basics of Laser Keyhole Welding or laser spot welding

In some sheet metal applications that require resistance spot welding, an automated laser keyhole welding process can save time and improve weld quality. The process is well-suited for welding some dissimilar metals, which can be difficult to weld properly with resistance spot welding because of differences in the physical, chemical, and mechanical properties of the base metals.

Laser keyhole welding uses a powerful laser beam to weld two workpieces together. A high-energy-density laser hits a small pinpointed spot on the material. When light hits the top surface, it melts and vaporizes the metal. The pressure of the metal vapor pushes the liquid metal downward and aside, generating a keyhole. As the laser beam is moved across the surface, the keyhole follows the beam and creates a weld that is typically deep and narrow

In suitable applications, laser keyhole welding offers:

- Precise control of penetration depth, which eliminates any deformation or indentation on the back side of the bottom part. This reduces the time and money spent on postweld grinding or touchups.

- A very small beam size — less than 1 mm — that results in a small heat-affected zone. This offers benefits when welding thin materials or metals in which controlling heat input is important.

- An extremely fast process that is typically three to four times faster than manual resistance spot welding.

- Consistency and predictability, which result in high-quality finished welds and reduced time and money spent on rework.

Laser spot welding

Fiber Laser Spot Welding

Laser spot welding is a non-contact process which uses a laser to create a single weld spot to weld metals together. Lasers are capable of delivering a pulse of light with accurate, repeatable energy and duration. When the pulse is focused into one place – a small spot – (adjustable anywhere from approximately 0.1 to 3.0 mm in diameter) on the part, the energy density becomes quite large. The light is absorbed by the material causing a “keyhole effect” as the focused beam drills into, vaporizes, and melts some of the metal. As the pulse ends, the liquefied metal around the keyhole flows back in, solidifying and creating a small spot weld. This entire process just a few milliseconds.

Lasers can fire many pulses per second, and, by moving either the work piece or optics, allow either separate “spot” welds or a series of overlapping spot welds to create a laser seam weld that can be structurally sound and/or hermetic.

Considerations for Converting from resisitance spot welding to laser spot welding

Converting from resistance spot welding to laser keyhole welding requires considering several key factors to determine if it’s the right choice for the operation and application.

- Cost: Because our Wobble3+ series laser welding machines are very affordable, as well manual as automated versions, it requires an investment that is very feasable due to the very high and fast return on investment (ROI).

- Tolerance window for material: Proper tooling and fixturing are critical for success in standard laser welding. The two workpieces to be welded must be pressed together without a gap to create a high-quality laser weld. This makes the right joint and material presentation important, so the operation must be able to support proper setup and part fit-up. With our Wobble3+ Series we do overcome this barrier of critical fixture. The much higher margin of error on the joint alignement before welding possible and acceptable make it a valuble and economical alternative.

- Repetition: Laser keyhole welding is best-suited to a repetitive process in which many parts are produced, even if this means a high mix of parts with lower volumes of each part. Because of the necessary investment in system setup, applications with high repetition or high part volume typically offer the best ROI in laser welding. With our Wobble3+ Series we bring this investment down and make productions of lower part volumes very fast economical and profitable.

Laser Spot Welding Benefits:

Our WOBBLE-3+ and Wobble-6PRO+ handheld laser welders

can join a wide range of steels, nickel alloys, titanium, aluminium and copper.

Weld sizes:

Width: 0.1 mm - 3.0/4.0 nm

Depth: 0.1 nm - 6.0 mm

Welding speeds:

Range from 0 - 5 meter per second

Advantages of laser spot welding with our Wobble-Plus

The advantages of the laser technique, compared with arc or resistance welding processes are summarised as follows: