Battery Welding

Today’s electric vehicle batteries are designed for a life exceeding 10 years.

To ensure reliable operation over this lifespan, individual components and cells within the battery are connected with numerous welds.

The increased application for lithium batteries in electric cars and many electronic devices now utilize fiber laser welding in the product design. Components carrying electric current produced from copper or aluminum alloys join terminals using fiber laser welding to connect a series of cells in the battery.

Since the battery is expected to operate reliably for 10 or more years, these laser welds are consistently high quality. The bottom line: with the correct fiber laser welding equipment and process, laser welding is proven to consistently produce high quality welds in 3000 series aluminum alloys that have connections within dissimilar metal joints.

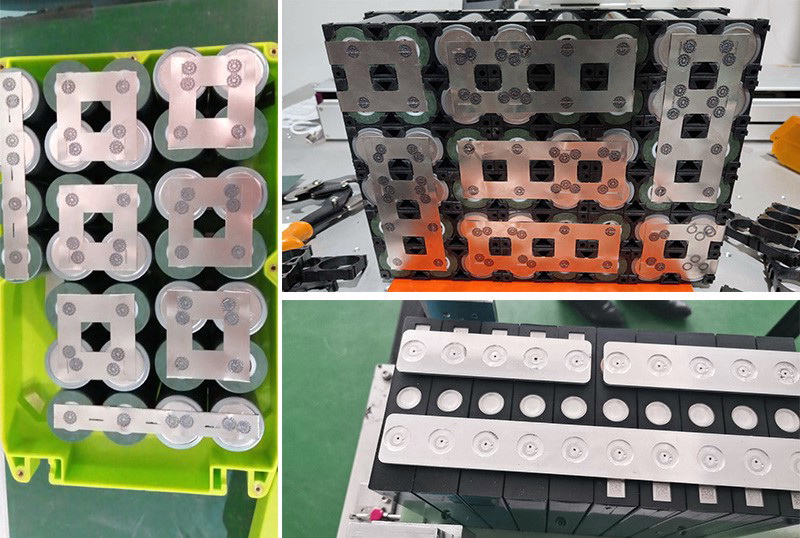

280A Big LifePO battery cells welding

The production of Li-ion batteries requires multiple welding processes.

Welded contact connections between the individual battery cells, for example, have proven to be more reliable,sustainable and above all cost-effective than bolted contacts or the use of bimetallic busbars.

The boxes of the rigid battery geometries are also welded, because they have to be gas-tight up to a pressure of 40 bar. These types of welding connections must be entirely maintenance-free. Electric cars should soon be able to drive in all climate zones, amid great temperature fluctuations and on all of the world's roads, whether good or bad.

Since each individual cell of a battery pack delivers just a few volts of voltage at high current, they must be connected in series to achieve a sufficiently high module voltage. The terminal contacts made of aluminum and copper are connected for this purpose by preference by welding. This is technologically challenging, as the resulting weld seam is more brittle the more that the dissimilar metals mix, as is unavoidably the case in conventional laser welding. Brittle weld seams – without a doubt – are simply unacceptable given the advanced requirements of electromobility. Therefor we have our Wobble technological solution.

Battery welding with Wobble laser welding machine

The increased application for lithium batteries in electric cars and many electronic devices means fiber laser welding is used in the product design. Components carrying electric current produced from copper or aluminum alloys join terminals using fiber laser welding to connect a series of cells in the battery.

Aluminum alloys, typically 3000 series, and pure copper are laser welded to create electrical contact to positive and negative battery terminals. The full range of materials and material combinations used in batteries that are candidates for the new fiber laser welding processes.

Overlap, butt and fillet-welded joints make the various connections within the battery. Laser welding of tab material to negative and positive terminals creates the pack’s electrical contact. The final cell-assembly welding step, seam sealing of the aluminum cans, creates a barrier for the internal electrolyte.

Because the battery is expected to operate reliably for 10 or more years, these laser welds are consistently high quality. The bottom line: With the correct fiber laser welding equipment and process, laser welding is proven to consistently produce high-quality welds in 3000 series aluminum alloys that have connections within dissimilar metal joints.

Battery Welding Today’s electric vehicle batteries are designed for a life exceeding 10 years.

To ensure reliable operation over this lifespan, individual components and cells within the battery are connected with numerous welds.

Battery manufacture

With the current strong interest in energy storage, QCW lasers look set to play their role beside CW lasers. Welding of battery tabs at high speed using single laser pulses from a QCW laser is now well established. Dissimilar metal joints between aluminum and steel and even copper and aluminum have now been developed.

There are two approaches to achieving sufficient electrical contact in battery connections from laser welding:

- A spinning beam technique (WOBBLE) to produce spiral or small-diameter concentric ring welds

- A number of high-pulse-energy, single-pulse laser welds, one beside the other, on each tab

Using combinations of dissimilar metals produces welds that might not be recognized as such by welding metallurgists, but clever design of the modules to limit mechanical loads on these joints appears to have solved some of these issues. But Continuious Wave Welding with a wobble function stay far superior over the pulsed QCW if we consider the mechanical loads capacity: a circle has alway more contact than differnt points.

Should your operation convert from spot welding to laser keyhole welding?

Most manufacturers are looking for ways to save money and improve efficiency without negatively impacting quality. Manufacturing operations that are using resistance spot welding can reap significant productivity and quality benefits in some applications by converting to laser welding.

Implementing laser keyhole welding can result in a welding process that is three to four times faster compared to resistance spot welding, while also increasing weld quality and repeatability. However, laser welding may not be the right fit for every job. Keep several factors in mind when considering if laser welding is the best choice for your welding application.

Electrical challenges

The key aim for the electrical connections is to produce a joint with a low electrical resistance to reduce the energy loss through resistance and thermal heating, and so maintain the efficiency of the pack. This also helps to keep the temperature of the pack as low as possible during operation.

A high-temperature process such as resistive welding can expose the cell to enough heat to melt or disturb the safety vent, compromise seals or cause internal shorting in the cell. It can also create more fatigue in the cell, compromising the long-term reliability.

Laser Welding of batteries = High Speed Solution

As the laser Welding process is non contact and the beam is steered by motion of the head, the welding speed is determined by the tab materialsa nd thickness and the terminal material along with the selection of laser power. As an example a 0.4 mm thick nickel plated copper tab can be welded to an aluminum terminal in 10 milli Seconds

Using Lasers for Battery Tab Welding Applications

Battery Tabs Welding with laser

From a welding perspective, the most important aspects of tab welding are the thickness and material of both the tab and the terminal. Conductivity is the name of the game, so battery tabs are generally made of aluminum or copper, sometimes plated with nickel or tin. Terminals may be cold rolled steel, aluminum, or copper, depending upon the physical size of the finished battery.

The most common battery types are cylindrical lithium ion cells around the 18650 size (18 mm x 65 mm), large prismatic cells, and lithium polymer pouch cells. Each cell type has a different set of welding requirements.

Cylindrical batteries

The key to welding the cylindrical cell type lies in the negative terminal weld, where the battery tab is welded directly to the can as opposed to the separate platform on the positive side. The weld on the negative terminal must not penetrate the can thickness which is typically around 0.3mm. The thickness of the can dictates how thick the tab can be – a rule of thumb is that the tab should be 50-60 % that of the can. Cylindrical battery can material is usually nickel-plated steel, and the tab material nickel or tin-coated copper. Nickel plating is preferred over tin because it is more stable; tin’s very low boiling point can lead to weld porosity and excessive spatter.

Large prismatic batteries

These high capacity cells need thick tabs to ensure a sufficient current carrying cross-section to deliver the pack output. However, the tab connection needs only to deal with the capacity of a single cell. Therefore, thinning or “coining” of the thick tab material to enable a lap weld or creating a through hole for a fillet weld greatly reduces the size of the weld needed. This in turn reduces heat input to the can, which is always a concern when welding thicker tabs.

For a lap weld geometry, reducing the tab thickness to a 0.25-0.5 mm thickness enables sufficient weld area for strength and capacity while keeping the temperature during the weld low enough to avoid battery damage. Material selection is generally aluminum for both terminal and tab – recommended tab materials are 1080 and 1100. Avoid aluminum alloy 6061, which cracks when welded. If this material is already specified and cannot be changed, use a 4047 pre-form as a third material which will introduce a large amount of silicon into the weld, which prevents weld cracking.

Lithium polymer batteries

These pouch type cells, which are thin with a rectangular footprint, are really gaining traction for consumer electronics. The terminals on these batteries are made up of thin layers of copper and aluminum foil which are laser welded to tab of copper and aluminum respectively. This weld is traditionally made using ultrasonic technology due to the need to weld through a stack of foil, however, fiber laser welders are now being used for increased weld quality and strength.

The key to success in welding polymer batteries with a fiber laser is making sure that the foils are in close contact and you’re using a pulsed laser or even better a wobbling laser to avoid overheating.

Welding battery Tabs to battery Terminals

From a welding perspective, the important aspects of tab welding are the thickness and material of both the tab and the terminal.

Resistance welding is suited to welding nickel tab material up to 0.4 mm thickness, and nickel or steel clad copper tab material to around 0.3 mm thickness to a wide variety of terminal materials.

Laser welding is able to weld both thin and thick tab materials, with a capability of welding copper based or bi-metal tab material above and beyond 1.5 mm thickness

Although able to weld both thin and thick tab materials, laser welding is particularly well suited to addressing the needs of high power battery welding. The tab material used in the development of high power cells must be able to accommodate the associated higher capacities and power levels. In order to provide effcient energy transfer, a tab thickness of minimum 0.3 mm or greater is required, as is the use of more conductive materials. For high power lithium ion cells, the terminal material for certain battery manufacturers is different. Therefore the need for bi-metal and smart terminal design solutions is required. Defining the optimal tab material may require some development work both on the welding and material costing. In these cases, the laser is an invaluable tool that offers outstanding welding performance and flexibility.

Battery Pack Manufacturing Solutions

When planning an automated or semi automated solution based on our Wobble cube, the primary factors to consider are loading/unloading, motion and tooling that fit the planned production flow and production rate.

Loading and unloading can range from manual to conveyer or pick-and-place, motion options center around whether the laser head or the part will be moved, with options including XYZ tables and gantry’s or robotic manipulators. For tooling, the laser is non contact, so tooling of the parts can be achieved either by using a fixture that the batteries and tabs are loaded into, or using actuated tooling that is deployed prior to the welding process.

The most suitable technology and process for battery pack manufacture relates to a number of factors including the pack size, thickness and material of the tab itself, and the necessary production rate. Laser welding processes enable high quality volume production, and, of the two joining technologies today used, spot welding and laser welding, the selection is usually made based on the specific requirements in each situation, but laser welding is taking over very fast from the spot welding, especially with the excelent wobble laser welding technology.

Getting Better Performance and Higher Currents from Battery Packs

Bigger and more efficient batteries and tabs

Battery tabs have been getting more conductive and thicker over the last several years, as customers keep seeking better performance and higher currents from their battery packs. These thicker battery tabs are primarily made of nickel, but nickel-plated copper tabs are also being introduced due to their higher conductivity. We have had success welding thicker tabs, but have found that the nickel-plated copper tabs can be very difficult to weld. In any case, adding slots and projections to the tab design is required as they focus the current and minimize current shunting.

Welding success also depends in part upon the nature of the battery itself. Those with thick caps can handle the high force and current needed to weld the thicker tabs. If the battery caps are too thin, you may deform or blow through them when welding very thick, conductive tabs. In summary, welding the thicker, more conductive tabs used in today’s more efficient, higher capacity battery packs can be challenging, but welding success can be achieved by designing the parts correctly and selecting equipment that is best suited to the application.

Battery Tab Connections Welding

There are many joining requirements in battery manufacturing, including both internal and external connections and can or fill-plug sealing. Laser welding is often used to join the internal electrode materials that make up the internals of the cell. These are typically constructed from thin copper and aluminium foils. The remaining joints, including the connections inside the can and the external terminal tab connections, are suited to both resistance and laser welding. The decision to use one technology over another is determined both by the type of weld required and production requirements, such as high volume and material compatibility.

Welding of different battery types and battery components

Cylindrical Battery Welding

- Battery Cap welding

- End Cover welding

- Battery Module welding

- Battery Module Production Line

- Super Capacitor Module welding

- Fuel Cell Electric Pile Bind welding

- Busbar welding

- Copper Busbar welding, etc.

Prismatic Battery laser Welding / Module welding/ Battery Pack welding

- Battery Cell welding

- Connecting Sheet welding

- Top battery Cover welding

- Battery Sealing Pin welding

- Explosion-proof Valve Post Terminal welding

- Battery Module welding

- Battery PACK welding, etc.

Soft Pack Battery

Mobility soft package battery laser welding such as Soft Package PACK, Soft Package Module, etc.

Laser Wobble Welding in Battery Pack assembly

Growing EV battery market demands better joining solutions: Wobble laser Welding is the best

Laser Beam Welded Joints for Lithium-Ion Batteries

The growing electrification of vehicles and tools increases the demand for low resistance contacts. Today’s batteries for electric vehicles consist of large quantities of single battery cells to reach the desired nominal voltage and energy. Each single cell needs a contacting of its cell terminals, which raises the necessity of an automated contacting process with low joint resistances to reduce the energy loss in the cell transitions. A capable joining process suitable for highly electrically conductive materials like copper or aluminium is the laser beam welding.

Over the past years, the demand for large battery packs for electric vehicles (EV) has steadily increased with the ongoing electrification of the transportation sector and a growing demand for greater ranges. State of the art EV battery packs consist of a large quantity of cells connected in series to achieve the desired voltage level and in parallel in order to enable higher charge- and discharge-currents.

For example, the EV Tesla Model S comprises of total count of over 7000 type 18,650 battery cells inside its battery pack. A single defective connection can lead to failure or a reduction in performance.

The quality of the joint has a decisive influence on the sustainability and safety of electric vehicles: Increased resistance at a welded joint causes more heat loss at this spot and leads to an increased electrical and thermal load on the individual cells, which in turn can lead to failure or accelerated aging.

Laser beam welding is a promising technology to contact battery cells enabling automated, fast and precise production of conductive joints. In comparison to other conventional welding techniques, such as resistance spot welding, the laser beam welding has a reduced thermal energy input. Compared to ultrasonic welding, the laser beam welding technique does not induce a mechanical force. The resulting transition resistances are in the range of the basic material resistances. The overall performance of the battery pack is therefore improved by the reduction of the ohmic resistance of the joints and heat loss inside the battery cell.

High currents must flow through the welds between battery cells in order to deliver the electricity needed to power a battery electric vehicle. These welds are the bottleneck of the electric circuit. Electrical resistance causes the temperature in the welds to raise when a current is conducted. This temperature increase may be harmful to lithium-ion battery cells. Therefore, larger weld areas which are created with our wobble laser system, and thus lower resistance. Thewelds made by wobble welding system increase the mechanical strength of the welds drastic, and reduce the temperature and thermal stress at the joints. Considering this, Wobble Laser Welding is much more suitable for battery tab joining than other types of welding.

Furthermore, laser beam welding produces a small heat-affected zone. Hence, it is crucial to understand how much heat is generated in the weld and whether the heat can damage the battery. Lithium-ion batteries must operate within a safe and reliable operating area, which is restricted by temperature and voltage windows. Exceeding the restrictions of these windows will lead to rapid attenuation of battery performance and even result in safety problems.

In the context of production, laser beam welding is well suited to be integrated into almost fully automated production lines in the manufacturing process of battery packs and EVs.

Bonding session

A battery pack in an EV consists of a large number of individual battery cells that are held together mechanically and connected electrically. Making those mechanical and electrical connections poses several challenges, including the joining of multiple thin, highly conductive materials of varying thicknesses and potential damage through thermal or mechanical shock.

These factors drive the range of techniques for constructing a battery pack, from resistive and ultrasonic welding to micro arc welders, highpower lasers and even high magnetic fields.

The choice also varies with the type of cell, whether it be cylindrical, pouch or prismatic. The different cell types have different mechanical requirements, but they all need to be protected against high temperatures during the construction process.

Materials challenges

A battery pack has to use different materials, and this creates a challenge for joining dissimilar materials. It can create brittle intermetallic layers with higher electrical resistance and a brittle nature compared with the parent materials. Highly reflective surfaces can be a challenge for processes such as laser welding, while surface coatings or oxide layers can be a challenge for resistive or ultrasonic bonding.

The joint strength is of course vital, and a stronger bond takes longer to create with many techniques. However, the bonding has to be created with minimal vibration that can be transferred into the cells – a key challenge for ultrasonic systems and a big advance fort laser Welding.

Laser Wobble Welding – Flexible Weld dimensions

As laser welding has no limitation on the proximity of the welds, the laser can place any pattern of weld spots on the tab or with the wobbling technology the wobble laser can weeld any diameter of circle according to strength requirements. If the weld strength of the joint is achieved, conductivity follows.

For more conductive materials, the weld area required for strength can be as much as 10 times that required for conduction. Although peel strength remains an important weld test, vibration is also important. As vibration strength places an emphasis on having good weld strength in any direction, the circle weld of wobble welding provides the solution.