Laser Welding of Pillow Plates

CNC laser welding of pillow plates : finally accesable for every workshop!

WOBBLE CUBE: Affordable CNC laser welding machines with wobble function integrated for perfect welded pillow plates

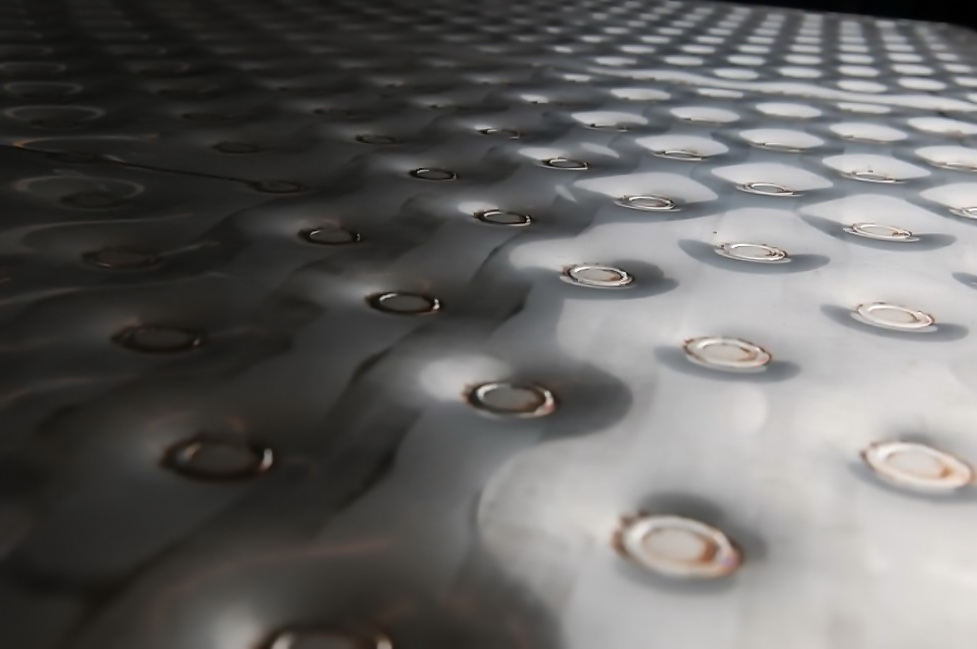

PillowPlate or dimpled jacket plates

Laser welded cooling plates

The wobble cube is able to produce PillowPlates which can be used for a large range of products, such as; heat exchangers, filter housings, falling film, square containers, cooled containers, offen walls, climate chambers, ice accumulators, pipes, heated or cooled vibration feeders and in cylindrical tanks, as well as in tanks of other shapes and designs, for example rectangular or oval ones. They can also be used for various industries for example food and beverage industries and other food-making and process industries. The surface can be brushed, polished or sandblasted. Possibilities are endless because you can produce every weld pattern shape and any required plate shape can be welded or engraved. The PillowPlates can be single or double embossed plates.

Pillowplate laser welding

The maximum product size depends on the width of the laser welding machine.

Pillowplates can be designed with thin top plates for the applicable working pressure. For instance with 1.0 mm plate we can reach a burst pressure of 180 bar. With 2.5 mm we can design heat exchanger plates with burst pressures of 400 – 500 bars. Generally 98% of the pillowplate material is stainless steel, 304L up to 254SMO.

The working pressure global guideline:

- Water / glycol / thermal oil: 1 – 5 bar

- Refrigerant Freon – NH3: 19 bar (at 20oC)

- CO2 refrigerant: 120 bar

- Steam: 0.5 – < 30 bar

Pillowplate specials

- Pillowplate pipes diameter 100+ mm

- Copper and titanium pillowplates

- Satellite simulation plates

- Cryogenic plates